Mechanical design tolerance plays a critical role in ensuring the quality and functionality of a product. However, issues related to tolerance can often arise, leading to challenges in manufacturing and assembly processes.

From excessive variations in dimensions to improper fits and clearances, these issues can result in defects, malfunctions, or even product failures. In this article, we will explore some common tolerance problems faced by mechanical designers and provide practical solutions to address them effectively.

By understanding and resolving these issues, engineers can improve the overall performance and reliability of their designs, leading to better quality products for end-users.

Understanding Common Mechanical Design Tolerance Issues

Understanding common mechanical design tolerance issues is crucial for engineers to ensure the overall functionality and performance of a product. Issues such as dimensional accuracy, surface finish, and geometric tolerances can greatly impact the quality of a design.

Dimensional accuracy refers to the deviation allowed in the dimensions of a part from its nominal value, while surface finish determines the smoothness or roughness of a parts exterior. Geometric tolerances, on the other hand, define the allowable variations in the shape and orientation of features on a component. By addressing these common tolerance issues, engineers can optimize the design process and ultimately prevent costly errors during manufacturing and assembly.

Addressing Dimensional Variation in Mechanical Designs

Managing dimensional variation in mechanical designs is a critical aspect of ensuring the functionality and performance of a product. Inaccurate tolerancing can lead to issues such as interference fits, parts that do not fit together properly, or even premature failure of the overall system.

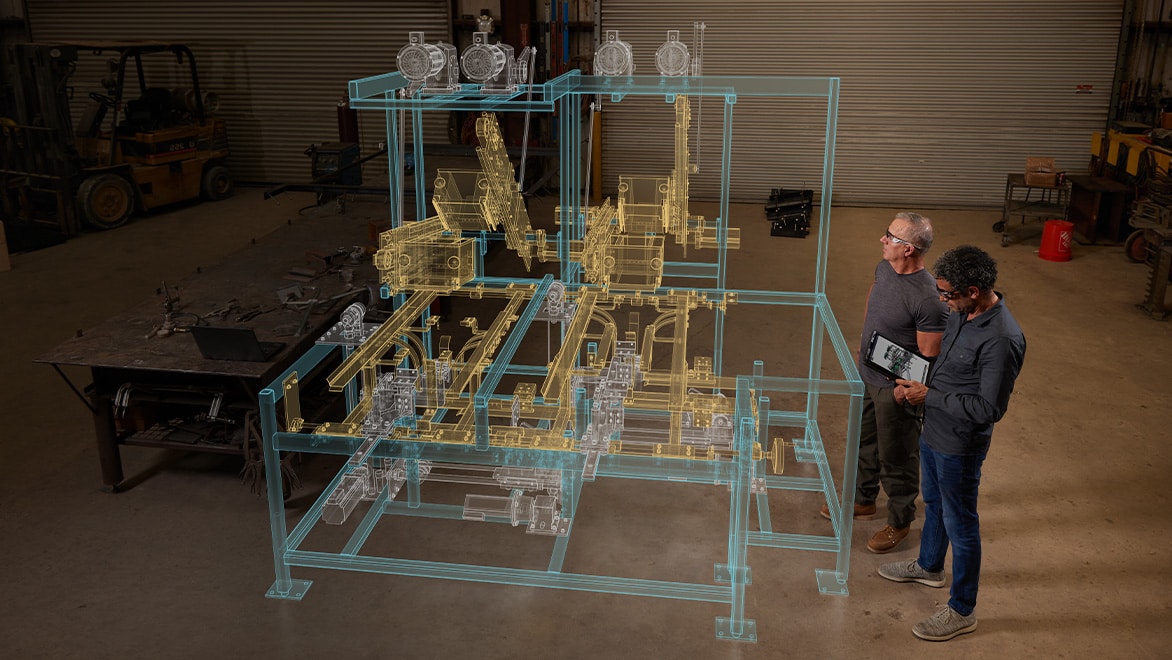

To address dimensional variation, designers must carefully consider the tolerances assigned to each dimension, taking into account factors such as material characteristics, manufacturing processes, and assembly methods. Utilizing tools such as tolerance analysis software can help identify areas of potential concern and optimize tolerances to minimize variation while still ensuring the overall integrity of the design.

By paying close attention to dimensional variation and implementing appropriate tolerance strategies, designers can create more reliable and efficient mechanical systems.

Tackling Geometric Tolerancing Challenges in Mechanical Designs

Tackling Geometric Tolerancing Challenges in Mechanical Designs requires a careful balance of precision and creativity. One of the common mechanical design tolerance issues is ensuring that all components fit together seamlessly while still allowing for proper functionality.

This can be particularly challenging when dealing with geometric tolerancing, as even the slightest deviation can have significant consequences on the overall performance of the mechanical system. To address these challenges, engineers must carefully analyze and adjust tolerances to ensure optimal performance without sacrificing quality.

By utilizing advanced software tools and techniques, engineers can effectively manage geometric tolerancing challenges to create designs that are both efficient and reliable.

Conclusion

In conclusion, understanding and addressing common mechanical design tolerance issues is crucial to ensuring the overall success of a project. By carefully considering factors such as material limitations, manufacturing processes, and assembly requirements, engineers can implement effective solutions to minimize the occurrence of costly errors and delays.

A thorough understanding of mechanical design tolerances allows for the creation of products that meet functional requirements while maintaining the desired level of precision and quality. By emphasizing the importance of precision and communication throughout the design process, engineers can optimize performance, reliability, and overall customer satisfaction.